Your Customers, Data And Market Are Continually Evolving. Are You Keeping Up?

Customer Success (CS) is not a “one-and-done” or “set it and forget it” motion. In today’s rapidly changing economy, your customers, data and market are constantly evolving, so you need to continuously improve your processes and operations to keep up.

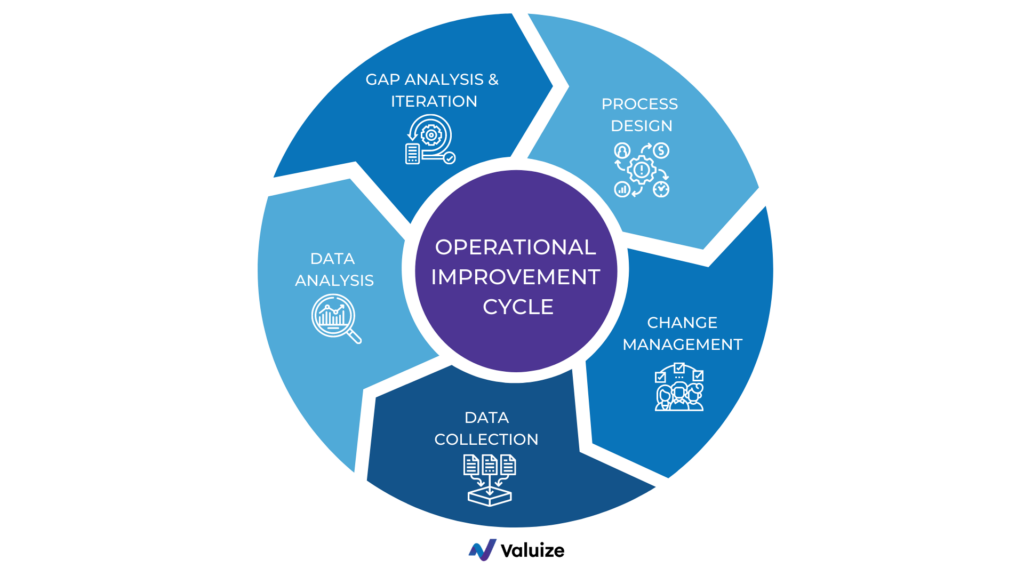

But how do you know if your current and new initiatives are actually providing value to your customers and your business? That’s where the operational improvement cycle comes in.

At its core, the operational improvement cycle is a continuous auditing tool that ensures you’re driving efficiency while eliminating activities that don’t provide any benefit. I realize I may have lost half of you by referring to it as an “audit tool,” but stick with me: by utilizing the operational improvement cycle, your end-to-end customer experience will remain relevant and produce value for your business and for your customers.

Recently, we spoke about effective capacity planning to deliver optimal customer value and derive the most out of your resources. Implementing an operational improvement cycle will improve the clarity of your capacity plan and help make incremental improvements to your Cost to Serve, customer value delivery, or both. Continuously testing and evaluating value-creating activities along your customer’s journey through the operational improvement cycle allows you to improve your processes and operations, assess and identify activities that actually drive value, and prune out activities that don’t.

In this article, we unravel the 5 stages of the operational improvement cycle to help you maximize the success of your business initiatives and reach peak organizational efficiency.

5 Stages Of The Operational Improvement Cycle

1. Process Design

While many business leaders think of processes as substantial mechanisms like systems or handoffs, a process is simply any activity that is prescriptive and repeatable. Brushing your teeth is a process. Making coffee is a process. Think lightweight, simple, repeatable. Process design consists of any change you make to how you’re doing things today. This could include testing a current and common task like success planning, making a change to your existing dashboard, updating your onboarding handoff from Sales to Customer Success, or testing an entirely new process within the organization like using Gainsight for the first time. All of these are examples of processes that can be audited and tested using the operational improvement cycle.

2. Change Management

Change management is about modifying the behavior of your employees. Many of us think documentation and training are the only tools needed to launch a new process. However, the more complex and critical the change in process is, the more impactful true change management will be to your success. Change management starts in your team’s hearts and minds; increasingly, employees want to understand not only what is changing but why the change is being made. Communicate early and often that a big change is coming to help your team adapt to the idea before they have to alter their behavior. Tell them why the change is happening and why it will help improve their day. Make sure leadership understands the change and is ready to model changed behavior as well.

Once you have the support structures in place (communication, the why and management support), plan your enablement calendar. Break down training into reasonable sessions, ideally one hour or less per session. Train the team and give actionable next steps for how they are expected to start using the new process; this is where your data will come from for the next step. Once the documentation is available and training is complete, follow up with regularly scheduled office hours and checkpoints with both the managers and their teams.

3. Data Collection

One of the most crucial components of the operational improvement cycle is collecting data on the implementation of your process. Inaccurate or incomplete data (or worse, no data at all) will make your operational improvement cycle meaningless. You need data to be able to generate insights into how all stakeholders are adopting the change and to determine if your new process is actually providing value.

To ensure that you can complete this step, you need to install a reliable data collection process that is routinely updated and easily accessible. You can incorporate this step directly into the process itself. For example, if you’ve rolled out a new set of fields to be updated regularly, give a directive to backfill those fields for existing customers. This forces folks into the new process, lets them get familiar with the system or tool, provides you with potential feedback if something is too difficult or doesn’t flow correctly and lets you measure who is getting it done, who is struggling and who is avoiding the change.

4. Data Analysis

Once you have a bank of accurate and reliable data, you need to complete a thorough analysis of your key health measures and metrics. The insights you generate from this evaluation will help you execute a gap analysis and pinpoint areas for improvement. Consider the following questions as you analyze the data:

- Are your Customer Success Managers (CSMs) actually spending less time completing your new process?

- Are your resources distributed efficiently?

- Are your CSMs able to accommodate more customers?

- Are your customers reporting higher value achievement as a result of your new process? Or is their satisfaction actually lower?

- Is there still more room for improvement? Can you make your process even better?

5. Gap Analysis & Iteration

A gap analysis is an analysis of the disparity between what you expected would happen as a result of implementing your new process, and the reality of what is actually happening.

Through a gap analysis, it’s common to discover that a process is too hard, too heavy, doesn’t make sense, or is in the wrong place. For example, we often see the case where a process rolls out fine initially but causes some unforeseen consequences, such as inadvertently increasing the amount of time spent preparing for a success plan. To combat this, you need to carry out a gap analysis to understand what is happening and why so that you can iterate, adjust or remove the process entirely. Then, you can go back into the improvement cycle to continue auditing and testing to ensure your processes are actually providing value and creating the desired outcome for your customers and your company.

Infuse The Operational Improvement Cycle Into Your Customer Success Operations Framework

Delivering value to customers in a fast-paced subscription economy is a delicate dance between new initiatives and continuous improvements. Running your process designs through a well-oiled operational improvement cycle will ensure that the tasks and activities your CSMs are performing are truly maximizing the efficiency and effectiveness of your business.

While all of your competitors are focused on customer centricity, stay three steps ahead with value centricity. Read our recent article about how to align your team, tools and processes around the power of value centricity.